Wire Erosion (EDM) Equipment at Cadmatic Engineering Services

Our ability to deliver quality, precision-engineered solutions, with innovative and considered thoughts is something we pride ourselves on.

Our range of equipment enables us to deliver a raft of services and we continue to invest heavily to maintain our competitive edge and ensure that you are working with experts with the tools to match.

ENGINEERING EQUIPMENT PLANT LIST

Wire Erosion (EDM) Specialist

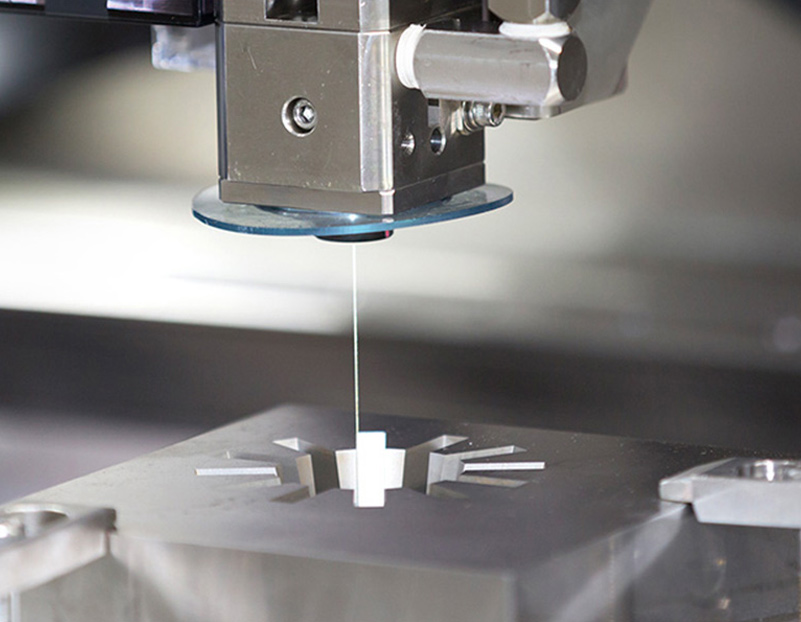

Wire Erosion is an incredibly important element in the services offered by Cadmatic Engineering, and we are proud to be able to provide Wire Erosion (EDM) through an excellent Mitsubishi Electric machine the MV2400S.

This superb machine provides economical production by a combination of high cutting speed and the trend-precision and low consumption. The MV-S series with the non-contact and therefore wear-free direct drive Tubular delivers less wire consumption and less power consumption so from a business perspective it ensures economic benefits. This combined with its reliability and man-free operation which is ensured by the patented wire threading.

CADMATIC ENGINEERING SERVICES EQUIPMENT

What is Wire Erosion?

Electrical discharge machining, also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges.

EDM (Electrical Discharge Machining) Wire Erosion is a precision engineering process where a work piece is cut through with a strand of wire, it creates electrical sparks between the wire and the work piece, and these electrical sparks cut the work piece.

ENGINEERING EQUIPMENT PLANT LIST

Wire Erosion

It’s a cost-effective method that has incredible accuracy on thicker component parts. Wire cutting machines can cut complex shapes even in tough materials.

The sparks are extremely controlled and in the more recent years to make sure that the cutting is accurate, dielectric deionised water is used. The water acts as a coolant to make sure the metal components don’t overheat and to wash away any particles that could get in the way. The wire erosion process starts towards the edge of a work piece or by drilling a hole where the process will start.