Surface Grinding Services at Cadmatic Engineering Services

With over 30 years’ experience Cadmatic Engineering Services Limited prides itself on its ability to deliver engineered solutions tailored around our clients’ specific requirements. Our focus on precision and quality, enables us to look at utilising our array of equipment to provide the best technical solution. In specific areas we use our surface grinding capability to deliver the exact requirements to meet both deadlines, quality expectations and budget considerations.

SURFACE GRINDING ENGINEERING

We pride ourselves on delivering solutions for our customers – Giving them one less thing to worry about.

We work tirelessly to understand the expectations, specifications, plans, budgets, and timing to provide a seamless solution, from the briefing and technical design stage to the completed order. All of this is attained through understanding functionality, and as a result delivering innovation, precision, quality, and attention to detail – These are all core elements at the centre of every project we deliver.

CADMATIC ENGINEERING SERVICES

What is Surface Grinding?

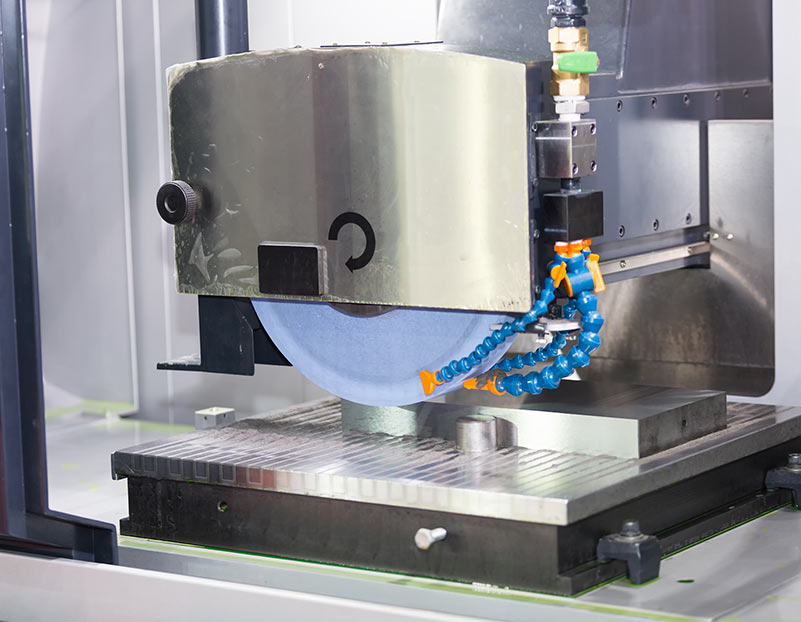

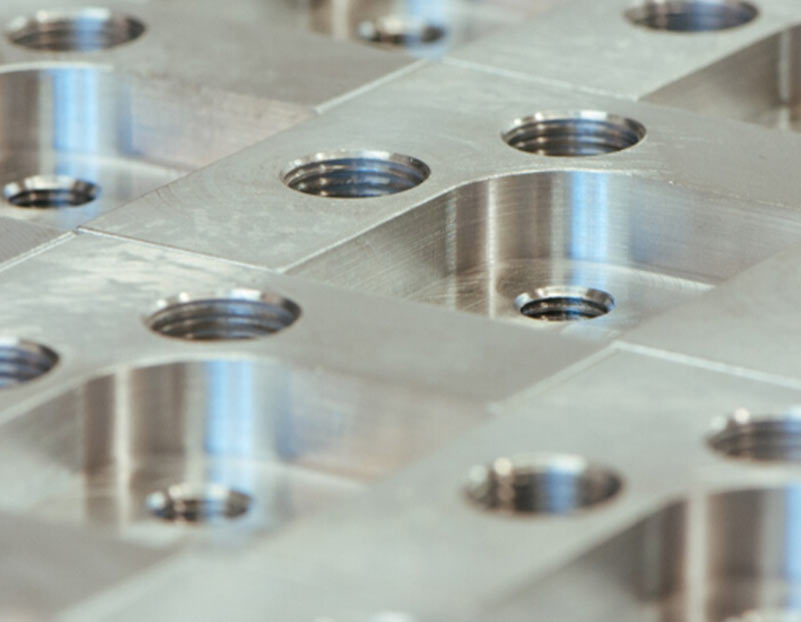

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles cuts chips of metallic or non-metallic substance from a workpiece, making a face of it flat or smooth.

Grinding is a material removal and surface generation process used to shape and finish components made of metals and other materials. The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling. Most abrasives used in industry are synthetic.

SURFACE GRINDING AT CADMATIC ENGINEERING SERVICES

Surface Grinding

Surface grinding is an abrasive process. It involves securing the object to a device that will hold it in place (a chuck) before slowly moving the object’s surface across a grinding wheel that’s spinning really fast. This will generate a flat plane wherever the machine comes into contact with the object. It also gives the object an even finish. The longer the wheel spends working on the cutting depth, as well as using a surface grinding wheel with a higher grit count will further improve the surface’s finish. By slowly increasing the depth of the cut the machinist will be able to achieve these things.