Other Services at Cadmatic Engineering Services

With a wealth of experience, Cadmatic Engineering Services Limited has both the knowledge and capability to understand your very specific and exacting requirements and deliver these seamlessly.

A wide range of services are available through Cadmatic Engineering.

We regularly process components which require Vacuum Hardening, Case Hardening, Plasma or Gas Nitriding, PVD Coating and Anodising to name a few.

CADMATIC ENGINEERING

Other Services

Our client focussed approach ensures we can provide an extremely high-quality solution to any engineering requirement.

We pride ourselves on the precision and quality of the work we deliver, ultimately aimed giving you complete peace of mind – Cadmatic Engineering Services Limited providing our customers with one less thing to worry about.

Hardening & Tempering

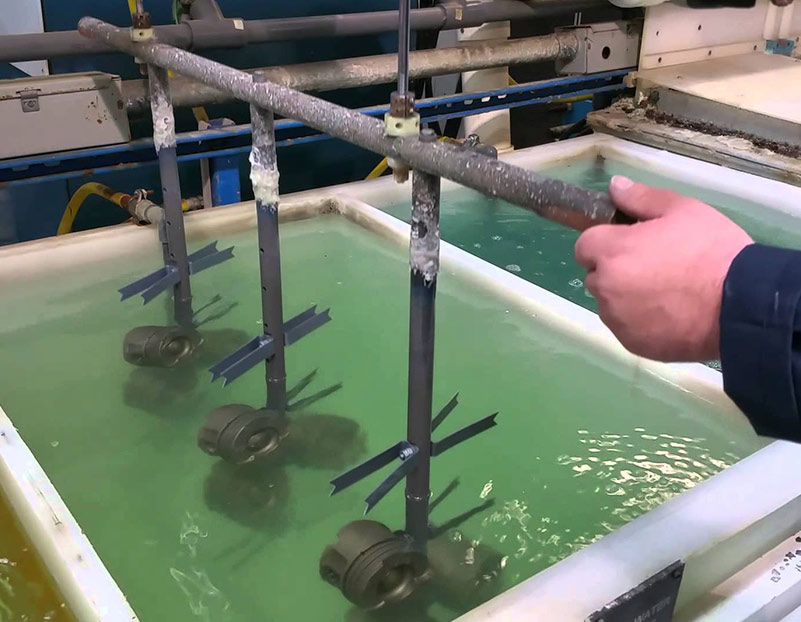

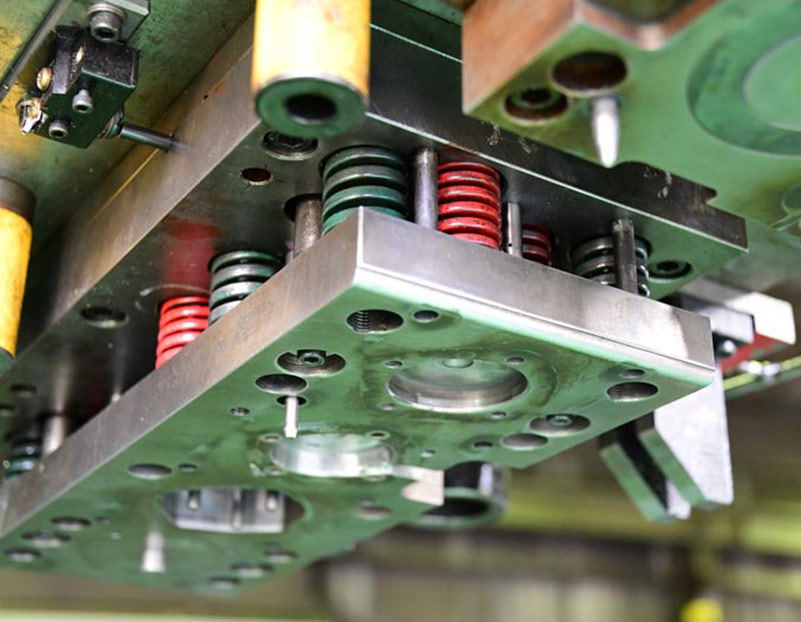

We achieve increased hardness (and therefore the strength) of steels using the vacuum hardening and tempering processes. This delivers through hardening of the material. Heat treatment processes are also used to increase fatigue life, wear resistance and, in some cases, corrosion properties. It is a tool and die heat treatment process, and is used to harden D2, to harden H13, and to harden tool steel.

Gas Nitriding

Why Nitride?

Gas Nitriding is normally carried out on hardened and tempered and fully stabilised parts to produce a hard wear resistant case, enhanced corrosion resistance and good fatigue performance.

The process is usually performed on fully finished components which, in many instances, require no additional operations prior to assembly.

Whilst Gas Nitriding is normally applied to low alloy steels it is possible to Nitride other materials such as stainless steel, titanium and nickel alloys, however the preferred nitriding route for those materials is Plasma Nitriding.

HARDENING / ANODISING / PLATING AT CADMATIC ENGINEERING SERVICES

Ask us about our other services

Our expertise helps guide you through every step of the process, whether creating a new part from specification to final delivery or redeveloping an existing part and needing recreate design and engineering drawings and specifications. Cadmatic Engineering Services Limited has the capability to answer your needs.

When you work with Cadmatic Engineering Services Limited you are working with a business whose success is linked to yours.