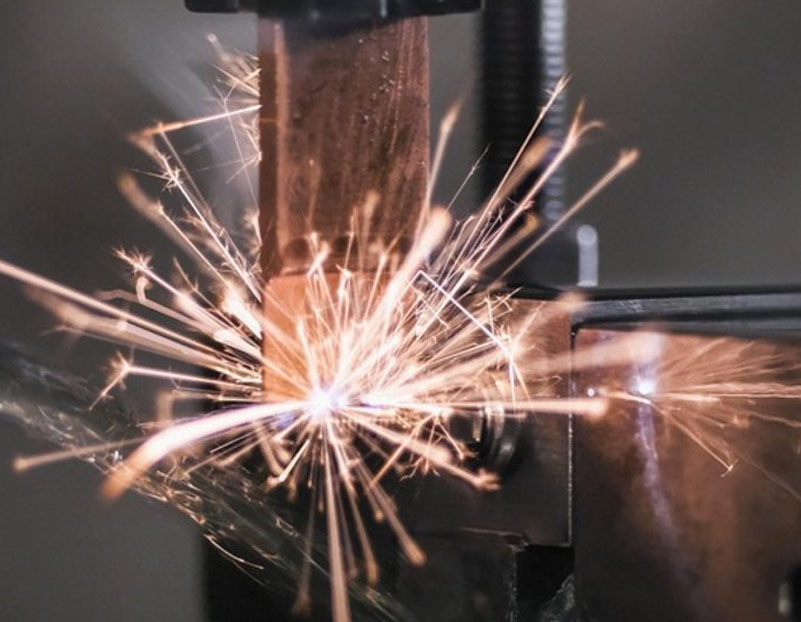

Spark Erosion (EDM) Equipment at Cadmatic Engineering Services

Our ability to deliver quality, precision-engineered solutions, with innovative and considered thoughts is something we pride ourselves on.

Our range of equipment enables us to deliver a raft of services and we continue to invest heavily to maintain our competitive edge and ensure that you are working with experts with the tools to match.

ENGINEERING EQUIPMENT PLANT LIST

Spark Erosion (EDM) Specialist

The process of spark erosion enables us to machine hardened or difficult to machine conductive materials to create shapes and forms that couldn’t be achieved with conventional CNC/Manual milling or turning.

Spark erosion allows Cadmatic Engineering Services to achieve intricate details that would, otherwise, be too complex or impossible to obtain with traditional cutting methods and is especially useful for alterations to hard materials such as press tools, or for removal of broken taps. It also allows for a good surface finish and the drilling of very small and fine holes.

So regardless of your engineering requirements, Cadmatic Engineering Services have the capability to provide a total solution.

CADMATIC ENGINEERING SERVICES EQUIPMENT

Cadmatic delivering precision and quality

Our Oscar Max ZNC S325 is a traditional type of sinker EDM machine giving us excellent capability and flexibility on smaller workpieces, delivering precision and quality.

The X and Y axis are operating manually with the hand wheel around the worktable. The worktable is 650 x 350mm, which makes it suitable for working on small workpiece and mould, such as: electrical components, mobile phones housing etc.

We know just how important it is that materials and parts are designed and produced to the highest of quality – and with the highest possible standards in mind. This is where Cadmatic Engineering comes to the fore. There are many different machining methods that can help you to create the piece you’re looking for, including spark erosion an area of specialism for Cadmatic Engineering – Call us now to discuss your specific requirements.

ENGINEERING EQUIPMENT PLANT LIST

What is Spark Erosion?

Spark erosion, also called Electro Discharge Machining, is useful to machine difficult shapes, as it has been used for decades as a means to create complex forms.

This machining method is typically used when producing intricate pieces. It is a process that creates a specific shape through the use of electrical discharges (sparks). More specifically, this machining process works by removing material from a piece with current discharges between two electrodes that are separated by a dielectric liquid that is subject to voltage. This fluid is both a conductor and a cooling agent during the process.

In order to remove this material, the process converts electrical energy into heat and initiates a melting process within the electrodes. There is no mechanical abrasion with spark erosion.

With this machining process, it is possible to achieve the desired design easily. Because there’s no contact between the tool and the piece, intricate sections or weak materials can be worked on without distortion.