CAD/CAM at Cadmatic Engineering Services

With a wealth of experience, Cadmatic Engineering Services Limited has both the knowledge and capability to understand your very specific and exacting requirements and deliver these seamlessly.

Cadmatic have years of experience as Tool & Die manufacturers.

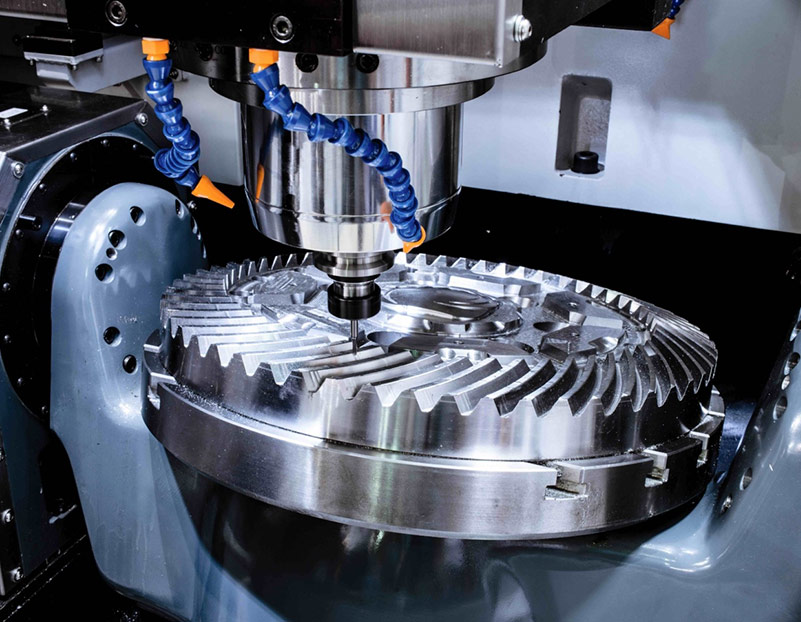

In Tool & Die manufacturing and all the other sectors we manufacture for, success depends on flexibility, speed, and superior finish. We constantly seek shorter cycle times and a precision finish.

This is why we use the latest CAM software from MasterCam to produce programs for our state of the art machine tools.

CAD/CAM ENGINEERING

CAD/CAM Specialists

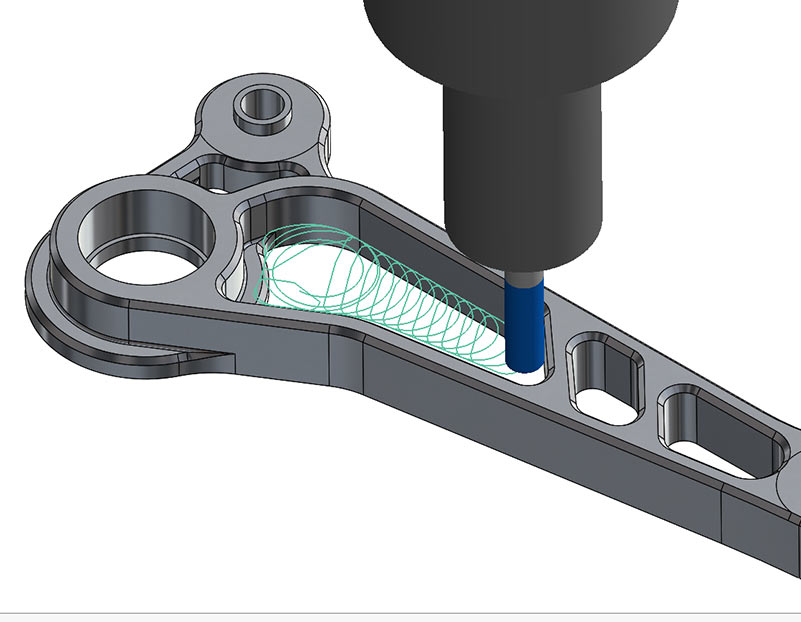

Utilising Mastercam, we bring precision and efficiency to your finished parts with high material removal rates in even the toughest materials used in the Tool & Die industry.

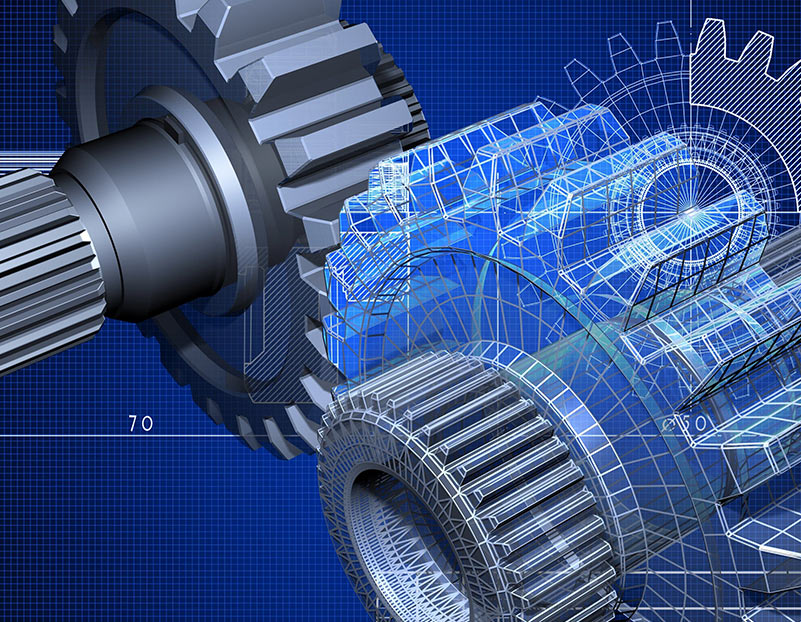

CAD is mainly used for detailed engineering of 3D models or 2D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components

CADMATIC ENGINEERING SERVICES

Cadmatic CAD/CAM

CAD/CAM applications are used to both design a product and program manufacturing processes, specifically, CNC machining. CAM software uses the models and assemblies created in CAD software, like Fusion 360, to generate toolpaths that drive machine tools to turn designs into physical parts.

Covering a range of services, our solutions delivers across a raft of areas. Always focused on precision, quality, attention to detail and recognition that dependability, confidence in our abilities and the need for solutions that meet both timing and budget expectations is crucial to ensure the service we provide is of the highest quality.

CAD/CAM AT CADMATIC ENGINEERING SERVICES

CAD/CAM Solutions

Cadmatic provides CAD/CAM manufacturing solutions to meet the most rigorous demands of industry, including:

- Ability to import, create, or cut virtually any CAD model.

- Wide range of CAM tools for solving complex machining issues.

- STL Compare checks a machining program against the CAD model for accuracy and quality assurance.

- Specialized motion for extended tool life and decreased cutting time.

When you work with Cadmatic Engineering Services Limited, you are in safe hands.